The PCB assembly industry is a cornerstone of modern technology, driving innovation in electronics manufacturing across sectors like consumer devices, automotive, aerospace, and healthcare. With the rise in demand for compact, efficient, and reliable electronic components, the industry has embraced transformative advancements and trends to stay ahead.

In this article, we’ll delve into the most impactful trends shaping the future of PCB assembly services, PCBA assembly factories, and PCB assembly manufacturers, while exploring the technologies redefining electronic circuit board assembly.

1. Automation Revolutionizing PCB Assembly

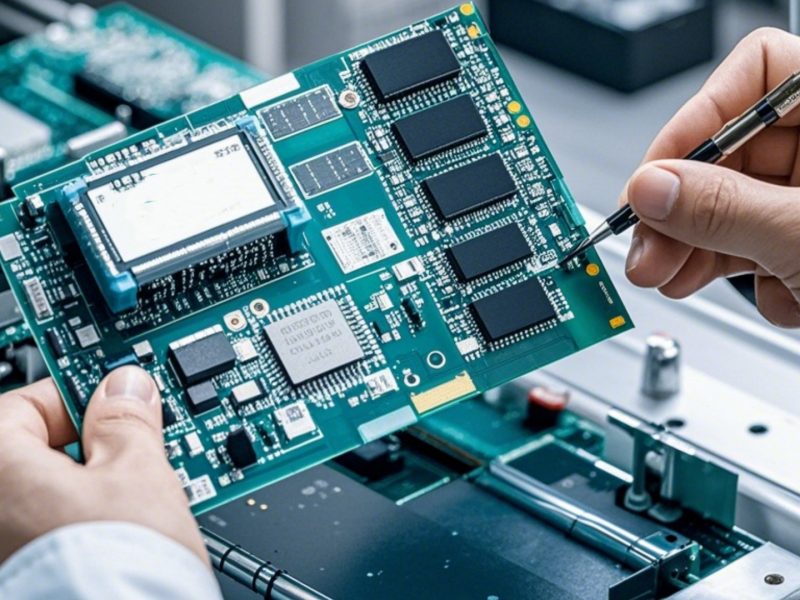

Automation is one of the most revolutionary forces in the PCB assembly industry. From circuit card assembly to electronic circuit board assembly, automated technologies like robotics, machine learning, and AI-powered tools are streamlining manufacturing processes.

Modern factories now integrate surface mount technology (SMT) and automated optical inspection (AOI) systems, ensuring precision in component placement and early defect detection. As a result,manufacturers can produce high-quality boards at unprecedented speeds, reducing human error and increasing operational efficiency.

Why It Matters:

- Automation ensures faster turnaround times for PCB assembly services.

- Improved precision reduces costly rework or failures in critical industries like aerospace and healthcare.

2. The Shift Toward High-Density Interconnect (HDI) Technology

As electronic devices become more compact, the industry is shifting to high-density interconnect (HDI) technology. HDI PCBs allow for smaller, lighter, and more efficient boards by utilizing finer traces and microvias, enabling suppliers to meet the demands of today’s advanced gadgets.

HDI technology is particularly critical in industries like telecommunications, where 5G and IoT devices require high-speed, low-latency performance. Leading manufacturers are adapting their production capabilities to accommodate this growing trend.

3. Sustainability in PCB Assembly

The global focus on sustainability has transformed the way PCB assembly services operate. Many factories now adopt eco-friendly practices such as lead-free soldering, recycling waste materials, and using energy-efficient equipment.

By integrating these green initiatives, manufacturers align with environmental regulations and meet the expectations of eco-conscious clients.

Key Sustainable Practices:

- Adoption of RoHS-compliant materials.

- Energy-efficient SMT machines in PCB assembly services.

- Reducing waste through advanced inventory management systems.

4. Advancements in Testing and Quality Control

Testing and quality control are critical in ensuring the reliability of PCBs, especially in safety-sensitive sectors such as automotive and healthcare. New methodologies like in-circuit testing (ICT), functional testing, and X-ray inspection have elevated the quality standards of PCBA assembly suppliers.

These advancements allow PCB assembly manufacturers to detect potential defects early in the process, ensuring the delivery of error-free boards.

5. The Rise of Flexible PCBs

With the proliferation of wearable devices, flexible PCBs have emerged as a game-changer. Unlike rigid boards, flexible PCBs can bend, twist, and conform to tight spaces, enabling innovation in medical devices, fitness trackers, and other compact gadgets.

Leading factories are now investing heavily in equipment capable of handling flexible PCBs, staying ahead of this rapidly growing market.

6. Localized PCB Assembly Services for Faster Turnaround

As supply chain disruptions become more common, many companies are turning to localized PCB assembly services to reduce lead times. This trend has led to the growth of smaller, regionally focused factories that provide quick, on-demand solutions.

By partnering with nearby manufacturers, businesses can streamline production cycles and improve communication, resulting in better outcomes for their projects.

7. Advanced Materials for High-Performance PCBs

The use of advanced materials like ceramic substrates and high-speed laminates has expanded the capabilities of PCB assembly services. These materials offer improved thermal management, signal integrity, and overall durability, making them ideal for demanding applications like automotive electronics and telecommunications.

PCBA assembly suppliers are investing in R&D to incorporate these materials into their production processes, ensuring they can meet evolving customer requirements.

8. Artificial Intelligence in PCB Design and Manufacturing

AI is not only revolutionizing PCB assembly manufacturing but also transforming how PCBs are designed. AI-driven software analyzes design schematics, optimizes layouts, and predicts potential failures before production begins.

On the factory floor, AI-powered tools perform predictive maintenance on machinery, minimizing downtime and ensuring seamless production in factories.

9. Enhanced Customer Experience Through Online Platforms

As technology advances, PCBA assembly suppliers are enhancing their customer experience by offering online platforms for PCB design, customization, and order tracking. These platforms make it easier for clients to submit specifications, receive instant quotes, and track their orders in real-time.

By embracing digital solutions,manufacturers are improving accessibility and fostering stronger relationships with customers.

Conclusion: A Thriving Future for PCB Assembly

The PCB assembly industry is undergoing a transformative phase, with advancements in automation, materials, and design reshaping the landscape. From factories implementing AI-powered systems to manufacturers embracing sustainability, the industry is poised for a dynamic future.

As the demand for compact, reliable, and high-performing devices continues to grow, PCB assembly services and PCBA assembly suppliers must stay ahead of these trends to thrive in an increasingly competitive market.

Whether you’re a business seeking innovative solutions or a manufacturer looking to expand your capabilities, staying informed about these trends is essential for long-term success.