In the rapidly advancing world of electronics manufacturing, two crucial terms often surface: SMT (Surface-Mount Technology) and PCBA (Printed Circuit Board Assembly). These processes play a fundamental role in creating the high-performance devices we rely on every day. Whether it’s smartphones, medical devices, or consumer electronics, understanding SMT and PCBA is essential for anyone interested in modern electronics.

This guide will break down SMT and PCBA, highlighting their significance, processes, and how they work together in electronics production.

What is SMT (Surface-Mount Technology)?

Surface-Mount Technology (SMT) refers to the method used to mount electronic components directly onto the surface of a printed circuit board (PCB). Unlike through-hole technology (THT), where components are inserted through holes in the board, SMT components are soldered directly onto the board’s surface, optimizing space and improving manufacturing efficiency.

Benefits of SMT in Electronics Manufacturing

- Space Efficiency: SMT enables the use of smaller, more compact components, which is crucial for creating miniaturized electronic devices.

- Faster Production: The automation of SMT processes, such as pick-and-place machines, accelerates the manufacturing timeline.

- Cost Reduction: By reducing component size and simplifying assembly, SMT lowers the overall cost of production.

- Improved Performance: Shorter electrical connections in SMT designs lead to enhanced signal integrity and faster device performance.

Common SMT Components

- Resistors

- Capacitors

- Diodes

- LEDs

- Integrated Circuits (ICs)

SMT has revolutionized the electronics industry, allowing for faster production cycles, better performance, and the creation of more compact and feature-rich electronic devices.

What is PCBA (Printed Circuit Board Assembly)?

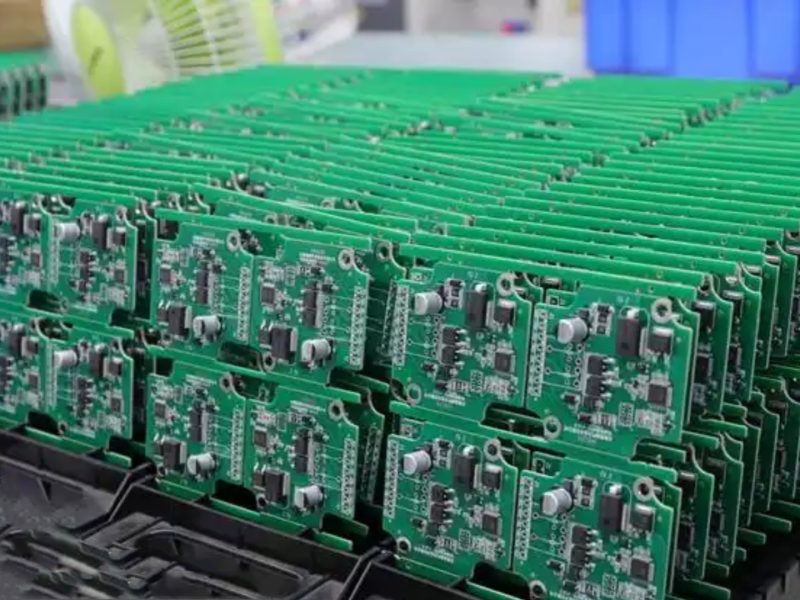

PCBA stands for Printed Circuit Board Assembly, the process of attaching electronic components to a PCB to create a fully functional circuit. The goal of PCBA is to transform an unpopulated PCB into a working unit, ready for use in electronic devices.

Key Stages of the PCBA Process

- Solder Paste Application: Solder paste is applied to the PCB at designated spots using a stencil.

- Component Placement: Components are accurately placed onto the solder-pasted areas by automated pick-and-place machines.

- Reflow Soldering: The board is heated in a reflow oven to melt the solder paste and form solid electrical connections.

- Inspection and Testing: Post-assembly, the PCB undergoes visual inspections and electrical testing (ICT) to ensure quality and functionality.

Types of PCBA

- Single-Sided PCBA: Components are placed on one side of the PCB.

- Double-Sided PCBA: Components are mounted on both sides for more complex designs.

- Multilayer PCBA: Multiple layers of PCBs are stacked to accommodate higher-density designs and advanced functionality.

The Relationship Between SMT and PCBA

While SMT specifically refers to the process of mounting components on the PCB surface, PCBA covers the entire assembly process. SMT is a critical part of the PCBA process, enabling efficient component placement and ensuring high-speed production.

In many manufacturing lines, SMT is the dominant method used to assemble components onto PCBs. However, some large or heavy components, which require greater mechanical strength, may still use Through-Hole Technology (THT). The combination of SMT and THT ensures that electronic devices meet performance, durability, and functionality standards.

Why SMT and PCBA Matter in Electronics Manufacturing

SMT and PCBA are at the heart of modern electronics manufacturing. These processes enable the production of compact, high-performance devices that power today’s most popular consumer electronics. The rise of smart devices, wearable tech, automotive electronics, and medical technology owes much of its development to the efficiencies of SMT and PCBA.

As demand for smaller, faster, and more powerful devices grows, these technologies will continue to evolve, pushing the boundaries of innovation in electronics manufacturing.

Conclusion

In summary, Surface-Mount Technology (SMT) and Printed Circuit Board Assembly (PCBA) are essential for the efficient, high-quality production of modern electronics. SMT enables the mounting of smaller components with speed and precision, while PCBA is the broader assembly process that transforms a bare PCB into a fully functional circuit. Together, these processes allow for the creation of the advanced, compact, and reliable electronic devices that power our daily lives.

By understanding SMT and PCBA, manufacturers can better navigate the complexities of electronics production and stay ahead of industry trends. These technologies are not just central to current manufacturing practices; they will continue to shape the future of electronics for years to come.

Frequently Asked Questions (FAQs)

1、What is the the SMT process?